From crimping with a diverse range of applicators, to custom processing with reliable soldering technology by certified soldering technicians, Iwasaki can handle all your harness processing needs.

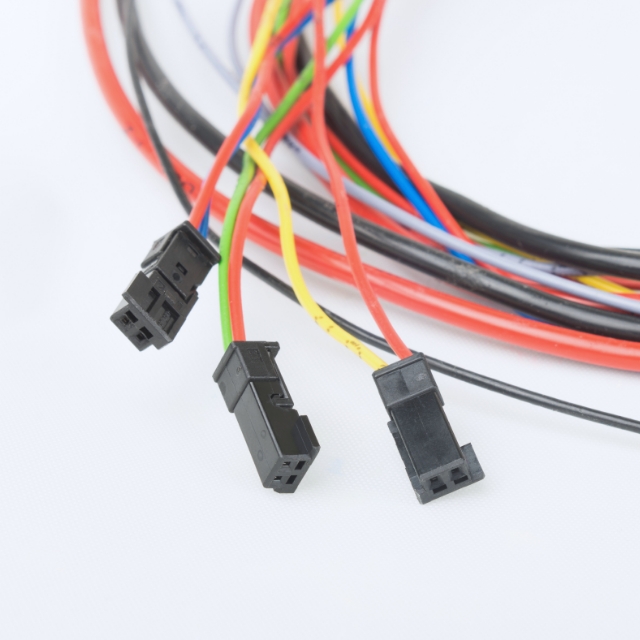

Harness Processing

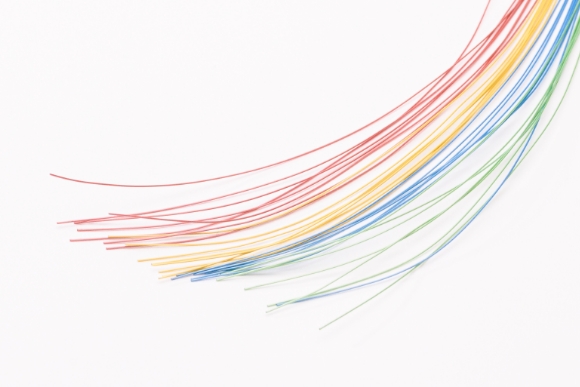

Iwasaki produces a variety of harnesses based on customer specifications. We specialize not only in ultrafine wire processing, but also in standard wire such as thick wire, and offer an end-to-end solution from assembly, to difficult harness processing. Iwasaki is always ready to discuss and come up with the perfect solutions to your special processing requirements, as well as any areas that require improvements.

Applicable industries

- Medical treatment

- R&D

- Imaging

- Consumer products

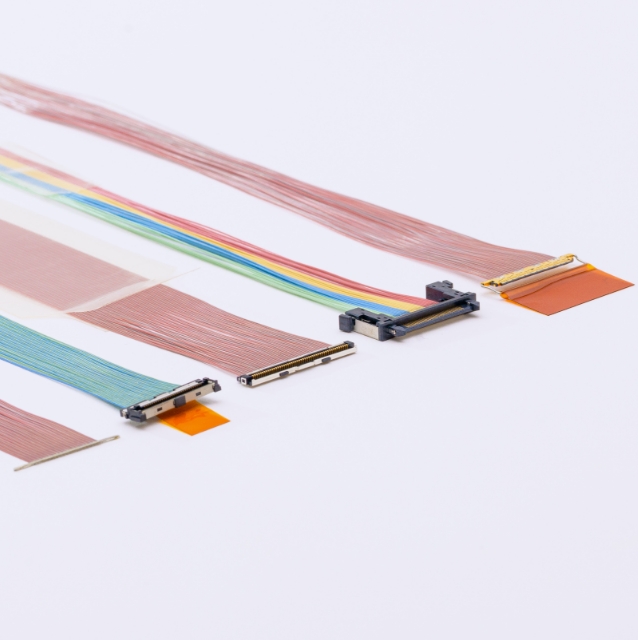

- Solutions for a Wide Range of Processing

- Iwasaki offers a variety of standard harness machining solutions from semi-auto crimping, auto crimping, soldering, and twisting, to potting. Iwasaki produces a variety of harnesses based on customer specifications, and has the perfect solutions to your special processing requirements, as well as any areas that require improvements.

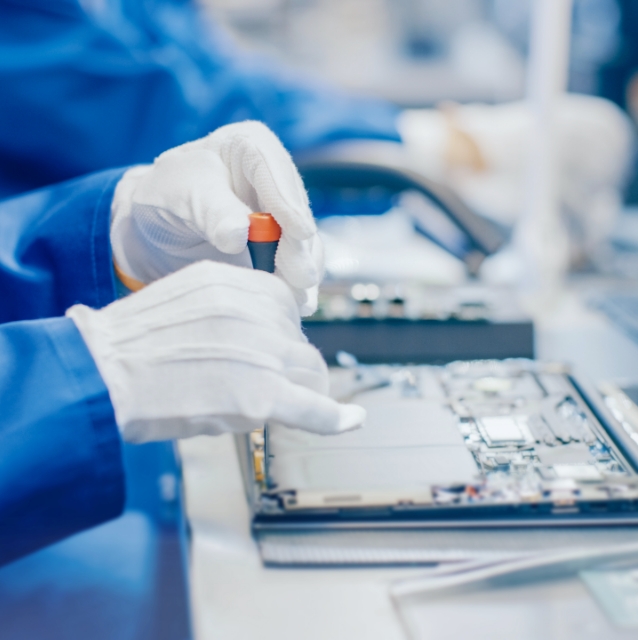

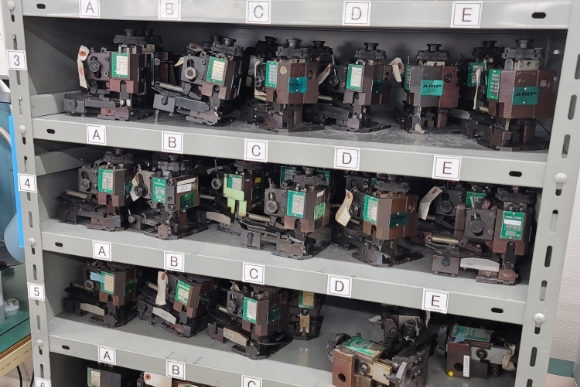

- Extensive Range of Dedicated Tools

-

Iwasaki also has over 500 types of dedicated tool (applicators, etc.). We carry out 100% inspections (electrical testing, appearance) to ensure the highest levels of quality.

* An applicator is a tool used for crimping machines.

Other Cable Processing Technologies and Equipment

Iwasaki has an extensive range of equipment from auto crimping machines capable of mass production, to our own in-house developed twisting machines in response to the needs of our customers.

Applicable industries

- Medical treatment

- R&D

- Imaging

- Consumer products

- In-house Developed Twisting Machine

-

Iwasaki can produce twisted cables easily with our in-house developed twisting machine. This simple, yet functional machine is also able to make adjustments to the amount of twist and unwind, twisted length, and even tension after twisting.

* This equipment is used to perform additional processing after soldering or crimping.

Hotmelt Molding

This method is completely different from the conventional simple hotmelting with a hand gun. The hotmelting machines used by Iwasaki are similar to low-pressure output molding machines, and are capable of demonstrating the power required for mass production. They are able to process the kind of moldings that are poured into a mold.

* Hotmelt molding machines are used to perform additional processing for cables that have been soldered or crimped.

Applicable industries

- Medical treatment

- R&D

- Imaging

- Consumer products

- Features of Hotmelt Molding

- Hotmelt molding has the following features.

- Outstanding insulation performance, high oil resistance

- Powerful holding force, excellent water tightness

- Low-cost mold fabrication

- Demonstrates power required for mass production

- Can also be used for waterproofing and potting.

- Compatible with range of materials based on application such as high-temperature materials

- Short hardening time, with hardening occurring immediately after pouring into mold