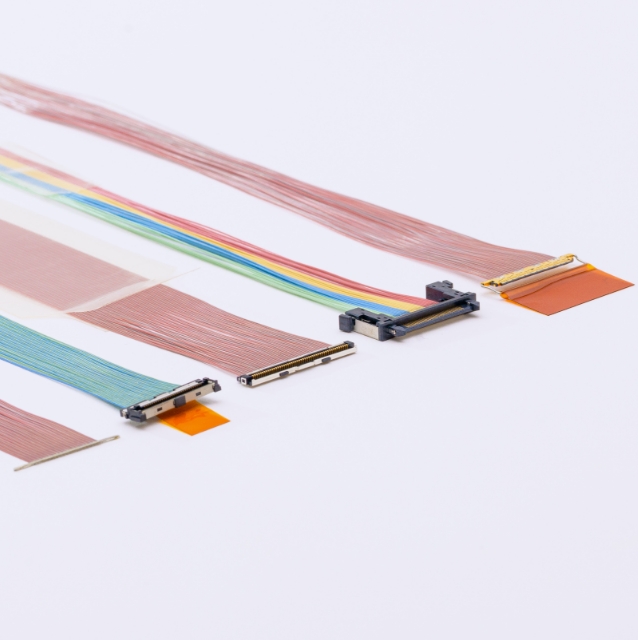

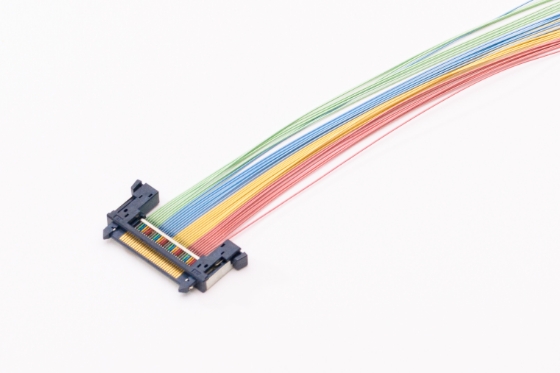

Iwasaki is a specialist in ultrafine coaxial line processing, and is always ready with solutions for even the most special cases!

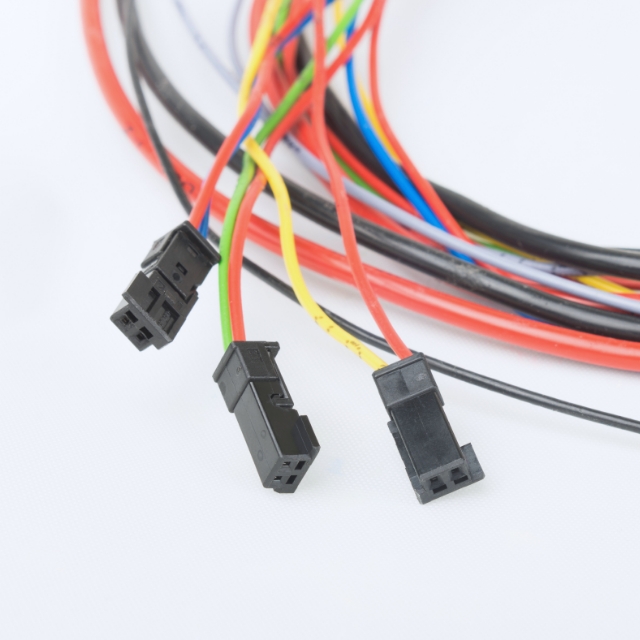

Our reliable technology is also perfectly suited to the processing of cables and harnesses for medical equipment, and offers peace of mind when it comes to high-performance products where characteristic impedance can be a concern

Non-contact Laser Processing

With transmission systems involving images and communication, there is a risk of damage to internal conductors when stripping with cutters, etc., and this can cause serious problems with data transmission performance. There is also a risk of issues with flexibility and strength, but the risk is reduced by processing with lasers.

Applicable industries

- Medical treatment

- R&D

- Imaging

- Consumer products

- Aerospace

- High-speed communications

- Safe, 2-stage Processing

- Processing shields and insulation in stages with 2 types of non-contact laser prevents damage to internal conductors. This method is widely used in communication systems and imaging systems.

- Compatible Coaxial Lines

- Iwasaki can process coaxial lines up to AWG52, and handle connector assembly. Please don’t hesitate to contact us to discuss materials that are difficult to obtain.

- Advanced Equipment

- Iwasaki’s equipment can strip wires using a laser to prevent contact with conductors.

- Coaxial Processing Types

- Iwasaki can handle staged processing using non-contact cutting of metallic braided shield only, and non-contact processing of plastic coating.

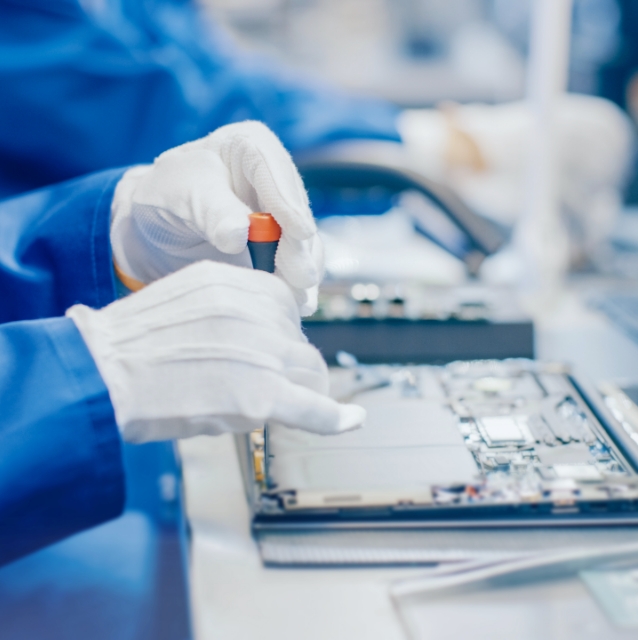

Microscopic Soldering

Soldered cables are the norm in a wide variety of applications ranging from those used in standard household appliances, to those used in cutting-edge products such as medical equipment and server equipment. However, Iwasaki provides microscopic soldering technology for use in extremely narrow locations for which standard soldering is normally difficult, and for use from the development stage of medical equipment, contributing to the development of a wide range of cutting-edge equipment.

Applicable industries

- Medical treatment

- R&D

- Imaging

- Consumer products

- Certification Systems

- Iwasaki has established various certification systems to ensure high quality in our product manufacturing processes. We have also put in place a professional human resource development program to ensure our employees have the necessary skills through annual training and tests. These systems are aimed at all those involved whenever the need arises, and have been designed to help us provide high-quality technology and deliver solutions to problems.

- Iwasaki’s Soldering Solutions

- Iwasaki specializes in microscopic processing, and offers problem-free soldering solutions for direct mounting on minute components, and for extremely narrow locations. We also have experience with AWG46 wire round solder and two-layer solder for 240-pin connectors. Please don’t hesitate to contact us to discuss your microscopic soldering needs such as medical scopes and product miniaturization.

- From Small-lot to Mass Production

- Iwasaki specializes in coaxial connection technology from standard AWG38 to 42 thin coaxial wire, to super-fine AWG49 and AWG52 wire. We also handle requests for custom applications such as dust-proof and low-profile cable, and welcome inquiries on technological challenges or quantity issues. We receive ultrafine coaxial processing inquiries from a variety of customers including medical, imaging, and consumer product equipment manufacturers, as well as from research and development institutions.